Industrial applications: PVC Flooring or Rubber?

A decade ago, wood or metal was the preferred means of flooring for industries. As time progressed, there were major innovations in the flooring industry. Rubber was made more pliable and introduced as an alternative and so was PVC flooring made more durable and cost effective.

We list down the major differences between PVC flooring and Rubber based flooring’s for various industries:

- Chemical Resistance: PVC flooring is compact and as a material known to be a lot less reactive than rubber. Major industries where chemicals are used depend on PVC flooring solutions. You can depend on vinyl flooring to stay in place without major damage in case of chemical leak, whereas rubber may even ignite and catch fire or melt away. When it comes to safety, do not make a compromise, and choose PVC over rubber.

- Static Resistance:Rubber carries static charges across its surface, making it highly dangerous for industries that use a lot of electronics. Static charge not only damages electronics but is also known to cause short circuits and interfering with the earthling wire installation. PVC on the other hand can be compounded to be highly anti-static. You will see most assembly lines, especially in the electronic industry relying on PVC flooring. PVC is one of the only flooring options that are completely anti-static. Marvel offers a range of anti-static flooring’s, contact us to share your application and we will recommend the most suited flooring product.

- Fire Resistance: Marvel’s industrial PVC flooring meets all Californian and European specs of fire retardency. Rubber on the other hand is highly inflammable. What’s worse is that the fumes from rubber burning are so toxic that it creates a new hazard altogether. No industry can meet safety standards without having a fire retardant solution. Consider Marvel’s PVC flooring as an option for your plant floor.

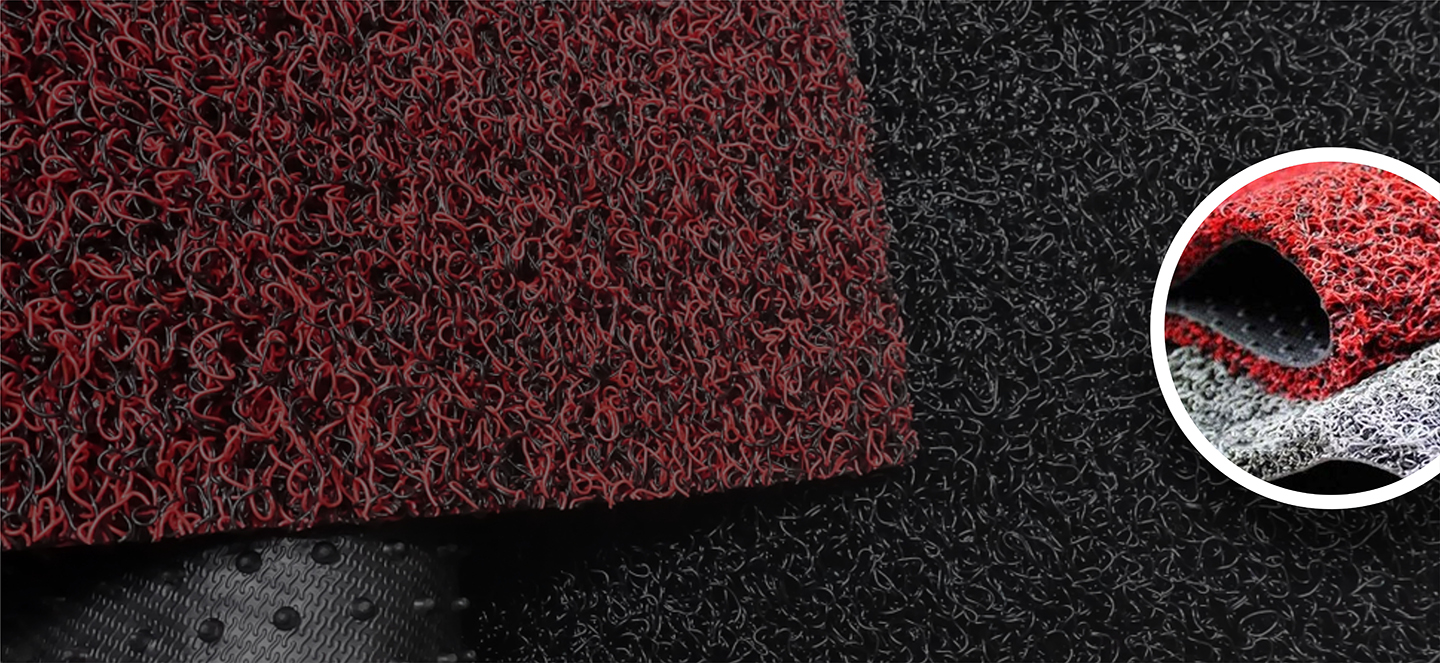

- Slip Resistance: This is one area where rubber excels. However, with the new compounds in PVC available, we are able to replicate the same rubber surface feel in PVC floor coverings. Moreover, with variety of textures, we can enhance the slip resistance further. Innovations in the field of rubberized compounds of PVC are rapid and we guarantee to match rubber slip resistance ratings in our customized flooring solutions. To get a quote, please send us an email.

- Air Quality: PVC flooring’s from Marvel meet the VOC ratings as per California state guidelines, the most stringent in the world! There are minimal to know volatile losses and even while burning the toxicity index is much lower than rubber. Rubber flooring on the other hand has high volatile losses, meaning the chemicals and plasticizers used escape to the air and surroundings. Special consideration if the flooring is required in closed areas like warehouses, commercial buildings or shop floors.

- Life Span: Due to all the factors mentioned above PVC has a much longer life span than rubber flooring’s. You can safely assume a much lower cost per year of usage if you calculate the need for replacement. Not to mention, save yourselves from the hassle of re-installation frequently by choosing a much long lasting solution.

- Electrical Insulation: PVC advances have made the material as a much better insulator than rubber. Marvel’s insulation mats shock-safe are certified for use by the Indian Government, with them banning use of rubber mats for electrical insulation.

All factors mentioned above should enable you to make the right choice while choosing the flooring for your business. Contact us to know more.

Related

- Industrial / PVC Flooring

Top 5 Advantages of PVC Membrane for Waterproofing Tunnels (2023)

By Marvel

- PVC Flooring

Marvel at Domotex Exhibition 2017

By Marvel

- PVC Flooring

Wooden Flooring: A Durable and Affordable Option for Your Home (2023)

By Marvel

- PVC Flooring

PVC Vinyl Cushion Mats

By Marvel

- PVC Flooring

Vinyl Flooring or Ceramic for your home?

By Marvel

- PVC Flooring

PVC Flooring: A Durable and Versatile Choice for Your Home (2023)

By Marvel

- PVC Flooring

Benefits of Choosing Printed PVC Flooring (2023)

By Marvel

- Artificial Leather / Plasticizers / PVC Flooring

Vocal for Local – Best Opportunity to Go Global!!

By Marvel

- Industrial / PVC Flooring

A Complete Guide: Tips for Choosing the Right Vinyl Flooring for Your Home [2024]

By Marvel![A Complete Guide: Tips for Choosing the Right Vinyl Flooring for Your Home [2024]](https://www.marvelvinyls.com/wp-content/uploads/2023/12/How-to-Install-Ceramic-Floor-Tile-Over-Linoleum-_-Hunker.jpg)