Top 5 Advantages of PVC Membrane for Waterproofing Tunnels (2023)

1. Introduction

Waterproofing tunnels is a critical aspect of underground infrastructure projects, as tunnels are susceptible to water ingress and moisture damage. To ensure the longevity and structural integrity of tunnels, selecting the right waterproofing material is crucial. PVC membrane has emerged as a leading choice in the field of tunnel waterproofing due to its exceptional properties and advantages.

PVC membrane, short for Polyvinyl Chloride membrane, is a synthetic material known for its durability, flexibility, and resistance to weathering. It is commonly used in various industries, including construction, due to its ability to create a seamless and watertight barrier. When it comes to tunnel waterproofing, PVC membrane plays a significant role in preventing water infiltration, protecting the structural components, and ensuring a safe and dry environment inside the tunnels.

In the following sections, we will delve into the top advantages of PVC membrane in waterproofing tunnels. These advantages encompass its durability, flexibility, weather resistance, low maintenance requirements, and energy efficiency. By understanding the benefits of PVC membrane, you can make informed decisions when it comes to choosing the right waterproofing solution for your tunnel projects.

ii) Choosing the right waterproofing material for tunnel projects is of utmost importance for several reasons:

- Structural Integrity: Tunnels are subjected to constant exposure to groundwater, moisture, and harsh environmental conditions. Without effective waterproofing, water can seep into the tunnel structure, leading to corrosion, erosion, and degradation of the materials. This can compromise the structural integrity of the tunnel and pose significant safety risks.

- Longevity and Lifecycle Costs: Tunnels are designed to have long lifespans, often spanning several decades. By selecting the appropriate waterproofing material, you can ensure that the tunnel remains watertight and protected from water-related damage throughout its lifecycle. Investing in a high-quality waterproofing system can minimize maintenance and repair costs over time.

- Operational Efficiency: Waterproofing sheet failures can cause disruptions to tunnel operations, leading to delays, closures, and increased maintenance efforts. Choosing the right waterproofing material that offers reliability and durability can help avoid such operational disruptions. It ensures the smooth functioning of tunnels, reducing downtime and associated costs.

- Safety and Environmental Impact: Tunnels often pass through sensitive areas, such as water bodies, ecosystems, or densely populated areas. Inadequate waterproofing can result in water pollution, mold growth, and compromised air quality inside the tunnels. By selecting a suitable waterproofing material, you can mitigate these risks and maintain a safe and healthy environment for tunnel users and nearby communities.

2. Durability and Longevity

Tunnels are subject to a wide range of demanding conditions that can put significant stress on their structures. These conditions include constant exposure to moisture, groundwater pressure, temperature fluctuations, and even chemical contaminants in some cases. The combination of these factors can lead to corrosion, erosion, and deterioration of tunnel materials over time.

To ensure the longevity and reliability of tunnel structures, it is crucial to choose a waterproofing material that offers exceptional durability. This is where PVC membrane shines. It is engineered to withstand the harshest conditions and maintain its integrity for extended periods.

The durability of waterproofing sheets is attributed to its inherent properties. It is highly resistant to impact, punctures, and tears, making it capable of withstanding mechanical stress and potential damage caused by heavy traffic or external forces. This resilience is particularly crucial in tunnels, where the constant movement of vehicles and people can exert considerable pressure on the waterproofing system.

Furthermore, it demonstrates excellent resistance to environmental factors that can cause deterioration. It is impervious to UV radiation, preventing degradation and discoloration over time. The membrane is also resistant to chemicals, including those present in groundwater, which can corrode or weaken other materials. By withstanding these challenging conditions, membrane ensures long-term protection and maintains the structural integrity of tunnels.

Choosing a durable waterproofing material like PVC membrane is essential to minimize maintenance and repair needs, reduce the risk of structural failure, and extend the lifespan of tunnels. By investing in a reliable and robust solution, tunnel operators can have confidence in the long-term durability and performance of their waterproofing systems.

3. Flexibility and Seamless Installation

Installing waterproofing sheet systems in tunnels can be a complex and challenging task due to several factors. These challenges include the presence of irregular surfaces, varying geometries, and the need to navigate around obstacles such as conduits, utility lines, or structural elements.

Tunnels often have uneven surfaces with varying angles, curves, and transitions. Traditional rigid waterproofing materials may struggle to conform to these irregularities, leading to gaps or compromised waterproofing integrity. Additionally, the limited accessibility within tunnels can make installation challenging, requiring specialized equipment and skilled labor.

PVC membrane stands out as an excellent solution for waterproofing tunnels due to its exceptional flexibility. Unlike rigid materials, It can adapt and conform to irregular surfaces, ensuring a seamless and continuous waterproofing layer.

The flexibility of PVC membrane allows it to be easily maneuvered and installed on various surface contours, regardless of their complexity. It can accommodate changes in elevation, curves, and transitions without compromising the waterproofing integrity. This flexibility ensures that every nook and cranny of the tunnel’s surfaces can be effectively sealed, minimizing the risk of water infiltration.

One of the key advantages of PVC membrane is its ability to conform to different shapes, contours, and obstacles encountered in tunnel installations. Whether it’s arches, corners, or protruding elements, it can be molded and shaped to fit seamlessly around them.

This capability of PVC membrane is particularly valuable in tunnel waterproofing, where there are often various obstructions, such as utility lines, beams, or conduits that need to be worked around. It can be easily cut, folded, and manipulated to ensure a tight and secure fit around these obstacles, creating a continuous waterproofing barrier.

By utilizing membrane’s flexibility, installers can achieve a precise and efficient installation, maximizing the effectiveness of the waterproofing system and minimizing the risk of water ingress. This adaptability ensures that the entire tunnel surface is effectively protected, regardless of its shape or the presence of obstacles.

4. Weather Resistance and Performance

The need for low-maintenance waterproofing solutions in tunnels stems from several factors related to the challenges and operational requirements of tunnel infrastructure. Here are some key reasons why low-maintenance waterproofing solutions are crucial in tunnels:

- Accessibility: Tunnels are often designed with limited accessibility, making routine maintenance and repairs challenging and time-consuming. Accessing and inspecting the waterproofing system can be difficult due to the confined spaces and complex layouts. By opting for a low-maintenance waterproofing solution, the frequency and intensity of maintenance activities can be significantly reduced, minimizing the need for frequent access and minimizing disruption to tunnel operations.

- Cost-Effectiveness: Tunnels are long-term investments, and the operational costs associated with maintenance and repairs can add up significantly over time. By choosing a low-maintenance waterproofing solution, tunnel operators can reduce long-term costs by minimizing the need for regular inspections, repairs, and replacements. This cost-effectiveness can contribute to the overall financial sustainability of the tunnel project.

- Time Efficiency: Tunnels are often critical transportation arteries, and any disruptions to their operations can have severe consequences. Opting for a low-maintenance waterproofing solution means less time spent on maintenance and repairs, reducing the risk of delays or closures. It ensures that the tunnel remains operational for longer periods, allowing for uninterrupted traffic flow and minimizing inconvenience to users.

- Reliability and Longevity: A low-maintenance waterproofing solution is designed to withstand the demanding conditions of tunnels over an extended period. It offers durability, resistance to environmental factors, and longevity, ensuring that the waterproofing system remains effective with minimal intervention. This reliability reduces the likelihood of unexpected failures or water infiltration, providing peace of mind to tunnel operators and users alike.

- Safety and Operational Continuity: Water infiltration in tunnels can pose serious safety risks, compromising the structural integrity and potentially leading to hazardous conditions for users. A low-maintenance waterproofing solution helps mitigate these risks by providing a robust and continuous barrier against water ingress. It ensures the safety of tunnel infrastructure and supports the smooth and uninterrupted operation of transportation systems within the tunnel.

By choosing a low-maintenance waterproofing solution, tunnel operators can benefit from reduced costs, increased operational efficiency, enhanced safety, and prolonged asset lifespan. It allows them to focus on the core functions of the tunnel while ensuring reliable and effective waterproofing protection without the burden of frequent maintenance requirements.

5. Energy Efficiency and Sustainability

Energy efficiency plays a significant role in tunnel projects, offering various benefits in terms of sustainability, cost savings, and environmental impact. Here are some key aspects highlighting the relevance of energy efficiency in tunnel projects:

- Cost Savings: Tunnels require extensive lighting, ventilation, and other energy-intensive systems to ensure safe and efficient operation. By implementing energy-efficient measures, such as efficient lighting fixtures, optimized ventilation systems, and intelligent controls, tunnels can reduce their energy consumption and associated costs. These cost savings can have a significant impact on the overall operational budget of tunnel projects.

- Environmental Impact: Tunnels contribute to energy consumption and greenhouse gas emissions. Implementing energy-efficient measures helps minimize the environmental footprint of tunnel projects. By reducing energy consumption, tunnels can contribute to mitigating climate change and improving air quality. Energy-efficient tunnels align with sustainability goals and demonstrate a commitment to reducing the environmental impact of transportation infrastructure.

- Regulatory Compliance: Many regions and jurisdictions have implemented regulations and standards aimed at promoting energy efficiency and reducing carbon emissions. Tunnel projects are often subject to these regulations, and compliance is necessary to meet environmental targets. Implementing energy-efficient measures in tunnel design and operation ensures compliance with these regulations and demonstrates a commitment to sustainable practices.

- Operational Reliability: Energy-efficient systems in tunnels can enhance operational reliability. For example, efficient lighting systems ensure adequate illumination while minimizing glare and providing better visibility for drivers. Optimized ventilation systems help maintain proper air quality and control temperature, reducing the risk of discomfort or fatigue for tunnel users. Energy-efficient systems contribute to a smooth and reliable tunnel operation.

- Public Perception and Image: Energy efficiency is increasingly valued by the public and stakeholders. Tunnels that prioritize energy-efficient practices and highlight their sustainability efforts create a positive perception among users and the community. Energy-efficient tunnels align with broader societal expectations of sustainable infrastructure and can enhance the image and reputation of the tunnel project and its operators.

In summary, energy efficiency is highly relevant in tunnel projects due to its potential for cost savings, environmental impact reduction, regulatory compliance, operational reliability, and positive public perception. By incorporating energy-efficient measures, tunnel projects can achieve long-term sustainability, optimize their operational performance, and contribute to a greener and more efficient transportation infrastructure.

6. Conclusion

PVC membrane offers several key advantages for waterproofing tunnels, making it an ideal choice for tunnel projects:

- Durability and Longevity: PVC membrane is highly durable and can withstand demanding tunnel conditions, including impact, punctures, and mechanical stress. Its resistance to UV radiation and chemicals ensures long-term performance, preserving the structural integrity of tunnels.

- Flexibility and Seamless Installation: It’s flexibility allows it to seamlessly adapt to irregular surfaces, contours, and obstacles within tunnels. It can be molded and shaped to fit any shape or curvature, ensuring a watertight seal even in challenging installation scenarios.

- Weather Resistance and Performance: It exhibits excellent resistance to weathering, including UV radiation, temperature variations, and chemical exposure. It maintains its performance and integrity even in extreme environmental conditions, ensuring reliable waterproofing for the entire lifespan of the tunnel.

- Low Maintenance and Cost Savings: It requires minimal maintenance, reducing the need for frequent inspections and repairs. This results in cost savings over the long term, as it minimizes maintenance expenses and operational disruptions associated with tunnel waterproofing.

- Energy Efficiency and Sustainability: It’s reflective surfaces contribute to energy efficiency by reducing heat absorption and cooling loads within tunnels. This energy-saving feature not only reduces operational costs but also aligns with sustainability goals by minimizing the environmental impact of tunnel projects.

By leveraging the advantages of PVC membrane, tunnel projects can benefit from long-lasting durability, efficient installation, reliable weather resistance, cost savings, and sustainable operations. It provides a robust and effective solution for waterproofing tunnels, ensuring their structural integrity and protecting them from water infiltration throughout their lifespan.

Related

- PVC Flooring

Wooden Flooring: A Durable and Affordable Option for Your Home (2023)

By Marvel

- PVC Flooring

PVC Flooring: A Durable and Versatile Choice for Your Home (2023)

By Marvel

- PVC Flooring

Vinyl Flooring or Ceramic for your home?

By Marvel

- PVC Flooring

Marvel at Domotex Exhibition 2017

By Marvel

- Artificial Leather / Plasticizers / PVC Flooring

Vocal for Local – Best Opportunity to Go Global!!

By Marvel

- PVC Flooring

Benefits of Choosing Printed PVC Flooring (2023)

By Marvel

- PVC Flooring

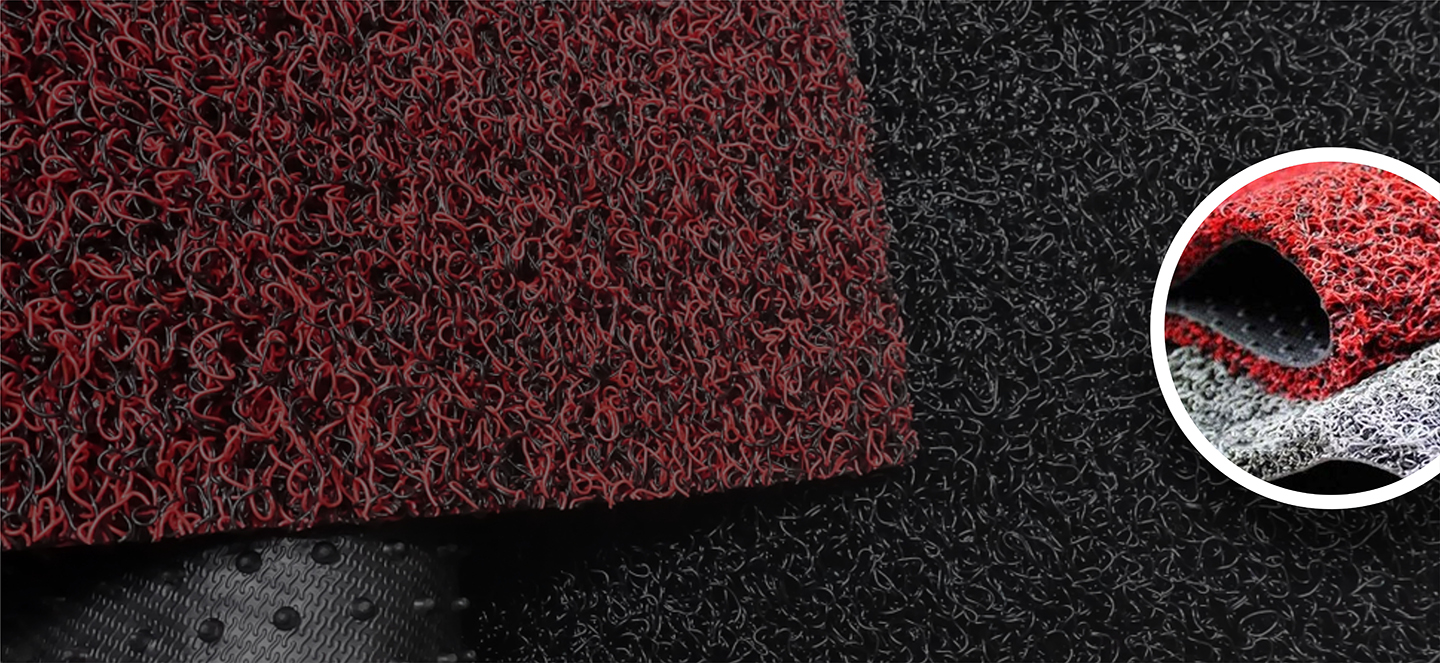

PVC Vinyl Cushion Mats

By Marvel

- Industrial / PVC Flooring

A Complete Guide: Tips for Choosing the Right Vinyl Flooring for Your Home [2024]

By Marvel![A Complete Guide: Tips for Choosing the Right Vinyl Flooring for Your Home [2024]](https://www.marvelvinyls.com/wp-content/uploads/2023/12/How-to-Install-Ceramic-Floor-Tile-Over-Linoleum-_-Hunker.jpg)

- PVC Flooring

Industrial applications: PVC Flooring or Rubber?

By Marvel